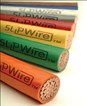

Cerro Wire Introduces Improved SLiPWire THHN Cable Jacketed With Self-Lubricating Polymer

THHN cable reduces labor and installation costs

Cerro Wire LLC, a leading manufacturer of copper electrical building wire and cable, now offers SLiPWire, a thermoplastic high heat-resistant nylon-coated (THHN) cable jacketed with a self-lubricating polymer that provides an improved, lower co-efficient of friction. SLiPWire reduces the time, labor and cost for installation, eliminates the materials and labor needed for lubricating the wire, and avoids messy clean-up activities. Independent testing confirms that SLiPWire is equivalent to, or better than, competing products in the copper building wire industry.

Intertek Testing Services, an independent testing laboratory, observed a test pull conducted at Cerro Wire's Ogden, Utah manufacturing facility, comparing SLiPWire with competing pre-lubricated THHN products. Intertek verified that the methodology and setup for the test was very well designed to replicate a typical installation and that SLiPWire is every bit the equal if not better than other contenders in the industry.

SLiPWire also uses Cerro Wire's True Sequential Footage technology, the only sequentially printed cable reel that provides accurate wire length with each cut. True Sequential Footage prevents the need to carry excess cable inventory, providing precision length, accurate footage, and cost control. It also uses Cerro Wire's Max Print identification system to quickly identify the size of the cable, which aids in selection, inspection and prevents costly errors.

SOURCE: Cerro Wire LLC